business guideMaterial Department

More than 430 years since its founding, based on the international standards of ISO9001/IATF16949 and ISO14001, we have the casting technology required by the world

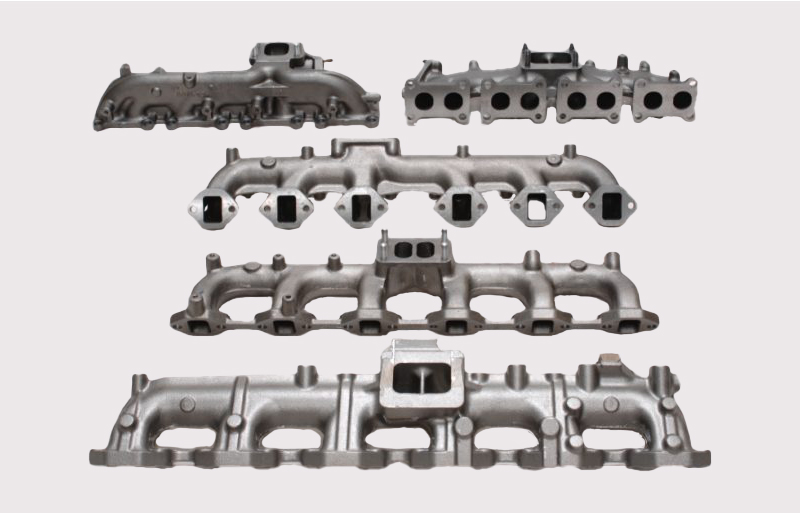

Challenge the world with thin, lightweight and heat-resistant manifolds and bearing housings demanded by the world!

In the field of “exhaust manifold”, which is mainly the part where hot exhaust gas comes out first after combustion in automobiles, we have been working on manufacturing from early on with the era of motorization, making use of the casting technology cultivated over many years. Especially in recent years, it has achieved a high reputation for casting of special materials with thin wall, light weight and high heat resistance required by the times.

In the field of “bearing housing” used for turbochargers, as a support industry of a Japanese manufacturer with a global market share of 20%, we are in charge as an important partner, at least in the world Our bearing housing is used in about 5% of the turbocharger. Our bearing housing is also used in turbochargers from major European car manufacturers, and when auditors from their home countries visited our company, their high technical capabilities were appreciated. In addition, the “turbine housing” also used for turbochargers is also our main product.

With the fusion of casting technology and IT cultivated over many years, “manufacturing of multi-variety, low-volume and multi-material products” that is strong in any era can be realized.

Yamato of technology

It has development capabilities tailored to the customer’s dedicated design.

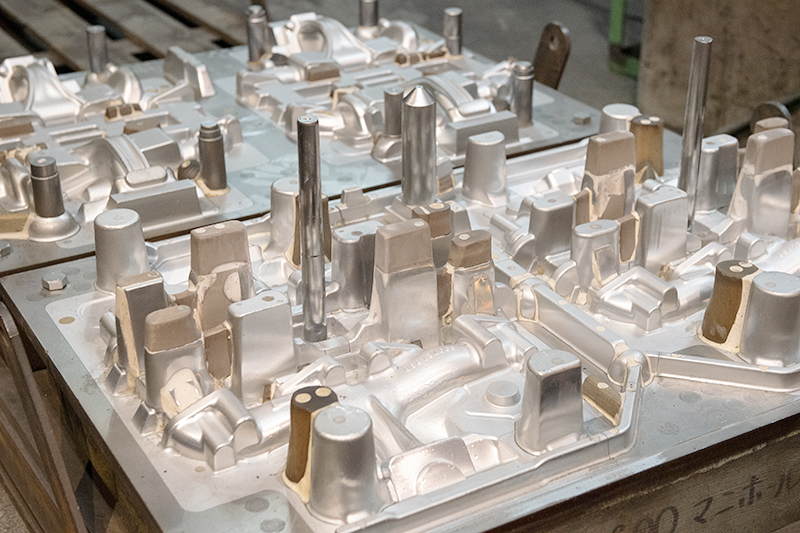

We have established our own casting technology and realized the improvement of the volume of processed finished products from materials by developing special technology for cores that form hollow parts of castings such as bearing housings.

Yamato of integrated production

The manufacturing process is integrated from casting material manufacturing to machining to meet the needs of customers.

Our company has developed not only high casting technology for many years, but also equipment and inspection jigs independently, and we have advanced IT from early on, and have technology specialized in both analog and digital, hardware and software.

Currently, the demand for gasoline turbochargers with small displacements with consideration for the global environment is increasing worldwide, and the bearing housing, which is part of its parts, is our main product, but our strength is only the technical strength in this field. Instead, we will keep in mind “creating high-mixed, small-volume and multi-material products” that can respond to any request in any era in the future, and we have no regrets in research and development.

As a casting industry, we will continue to be a company that takes into consideration the work environment and local environment.

As a consideration for the work environment, we have automated the transport of molten hot water in dissolved workplaces in high-heat work to reduce high-heat work and ensure safety. In addition, as a noise countermeasure for neighboring residents, we install soundproof walls, apply sound insulation materials to factory outdoor walls, and take measures against noise outside the factory.