business guideProcessing Department

It will stretch rapidly with the rise of casting technology.

An era that can’t go through as a foundry shop alone,

High processing technology that adds additional value to castings.

The cast product by the raw material part does not come out into the world as it is and become a part. Only by shaving it and making a hole that other parts can be incorporated, one part is made. No matter how high the cast product is finished, if poor quality processing is added, the evaluation as a part will go down. On the contrary, if high processing technology is added, it can add more value to the product.

Equipment with high inspection technology has also been developed, but there are still many things that you can only understand after shaving the casting. Therefore, processing the cast products made in-house in-house and putting them out to the world as finished products is directly related to the reduction of defects

In proportion to the increasing and growing demand of the technology of the material department, the demand of processing plants and the level required by customers are rapidly increasing. In response to this situation, rapid reforms are progressing, such as the introduction of not only general-purpose machines but also high-level special machines, systematization of work that does not rely only on craftsmanship, and individual level up.

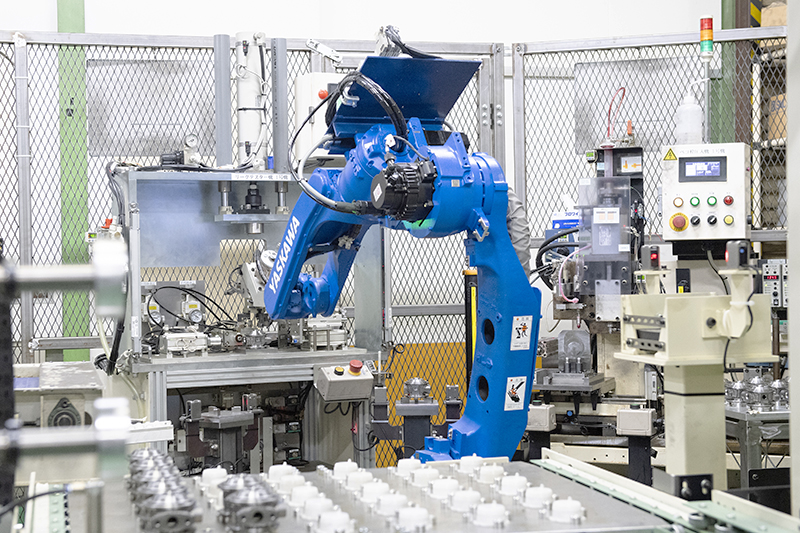

As part of that, we focused on bearing housings and established a new mass production processing line that introduced robots from 2014 to 2015. At the same time, we have also been certified by IATF16949, an international standard for quality assurance specialized in the automotive industry. However, the automobile industry itself is currently in a transitional period due to the rise of hybrid cars and electric cars. We are preparing to produce the parts that are needed while responding flexibly no matter how the industrial structure changes.

Processing technology to meet the needs of customers

Many of the cast products are machined as ready-to-use casting parts and delivered to customers as assembled parts.

Yamato of integrated production

There are 2 processing factories (750 tsubo in total), and various castings such as manifolds, turbine housings, and bearing caps are processed. 1Tsubo = 3.3 ㎡

Updating to modern processing machines

We have introduced the latest processing machines, including vertical and horizontal machining and NC lathes, for the purpose of improving the quality and processing capacity that meet customer requirements.